Advanced Materials

PVD Components

PVD-Materials blog

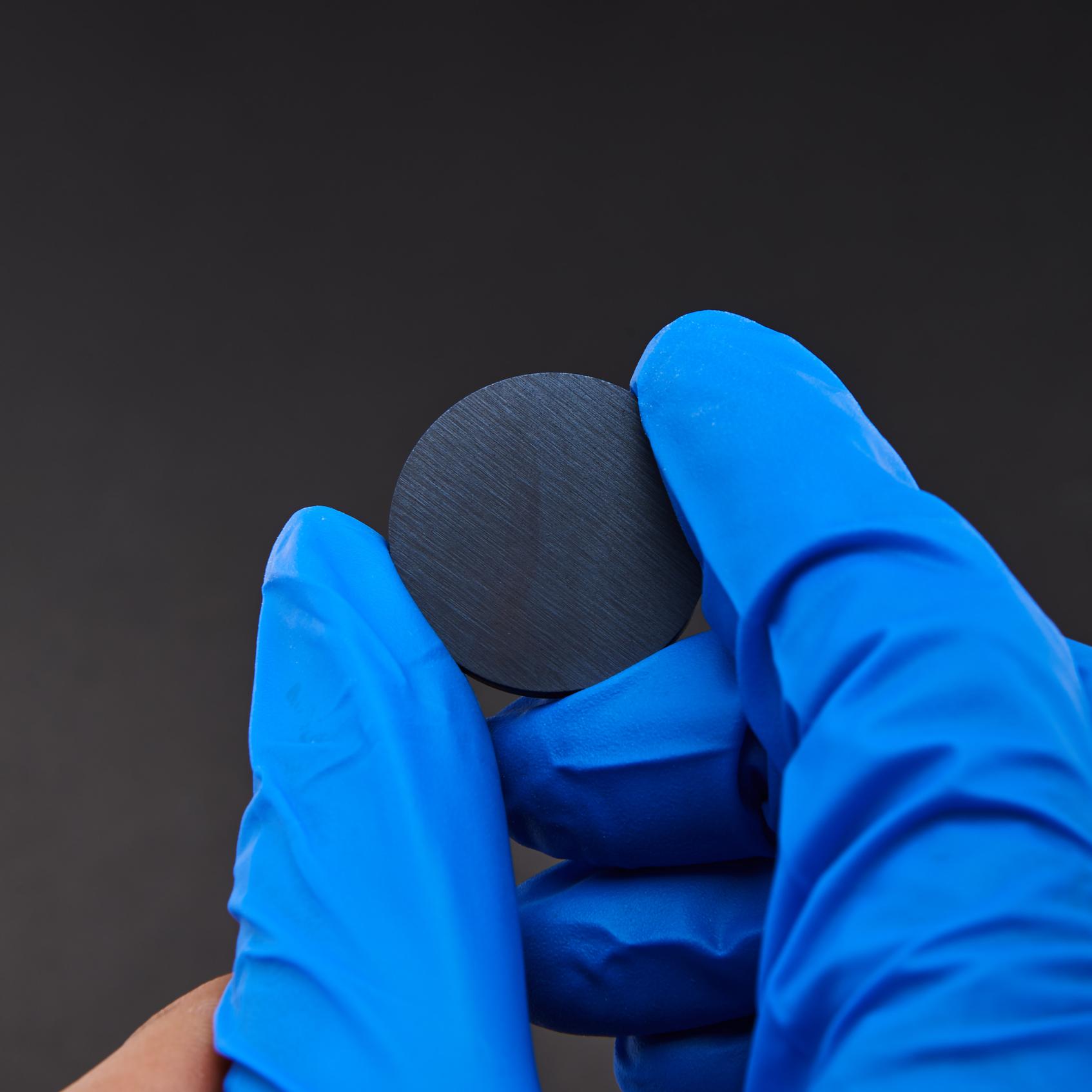

Physical vapor deposition (PVD) applications, e.g. in decoration

Performance characteristics of PVD coating

·Metallic appearance

·Uniform color

·A durable surface that permanently maintains a good appearance in a variety of basic air and direct sunlight conditions.

·The color is deep and bright

·Economical, it can reduce the time and cost of cleaning and polishing electroplating brass or gold.

·Harmless to the environment, avoid chemical poisoning, and VOC emission.

·Biocompatible

·Excellent adhesion – can be bent more than 90 degrees without cracking or peeling (PVD coating has high adhesion and durability). Other technologies, including electroplating and spraying, cannot be compared.

·You can etch any design you can imagine.

·It can be used for interior decoration or outdoor

·Oxidation resistance, corrosion resistance.

PVD decorative coating colors

PVD can be plated on stainless steel, copper, zinc-aluminum alloy, and other metals in gold, brass, rose gold, silver-white, black, smoke gray, copper, brown, purple, blue, wine red, bronze color, and other colors, and can provide the required color and quality according to your requirements. Check here for more details about PVD application in decorative coating

Scope of application

PVD technology is widely used in the processing and manufacturing of door and window hardware, kitchen hardware, lamps and lanterns, marine products, jewelry, handicrafts, and other decorative products.

Nowadays, PVD is very popular in the field of daily hardware. Many leading hardware manufacturers in the world have begun the development and mass production of PVD products. PVD's rich colors make it very easy to match, excellent anti harsh environment, and easy to clean, colorfast performance make it deeply loved by consumers. In particular, vanguard's star product, copper series coating, is widely used in the world and used to replace copper and copper-plated products.

For more information, here's a great blog about PVD technology